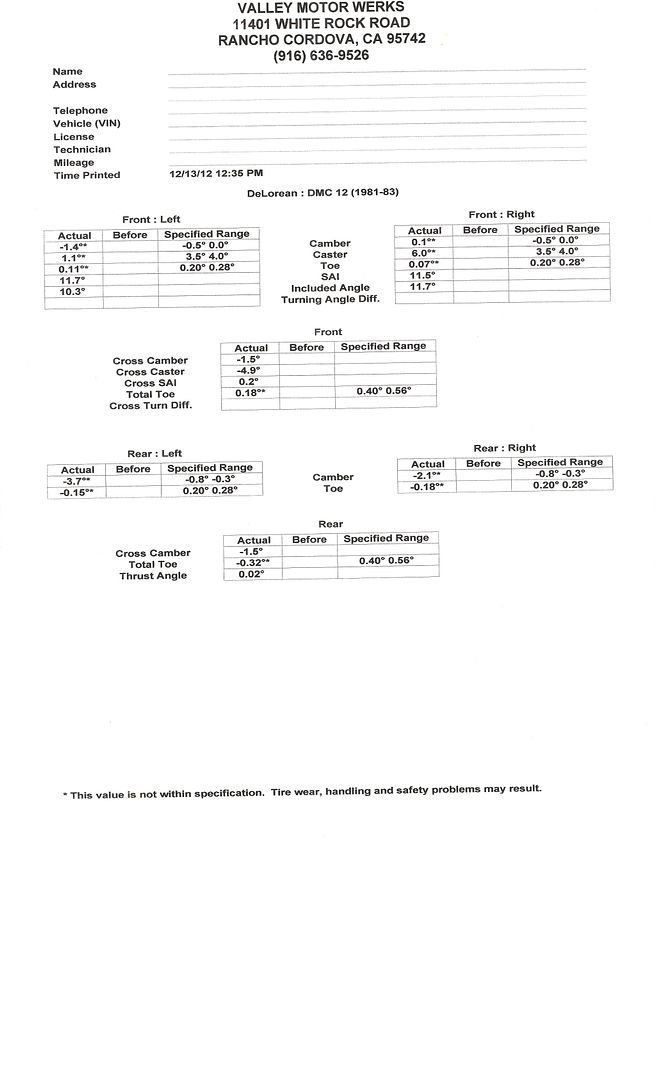

Its only taken nearly 4 years but I finally got my car on an alignment rack (most places didnt want to touch a DMC, others I wont let touch my DMC) at my new shop. My car has always pulled to the left pretty badly. Now I know exactly why. The rear toe is a bit off, that can be fixed with shims. and the camber is excessive and uneven( remember ive lowered the car about 3"), that can be fixed with adjustable links like DPI sells. But the front has issues. If you havent read my resto thread my car was an east coast rust bucket that probably has never been driven lovingly. So here is the run down of the alignment:

Front toe Spec: .20 to.28' in

Left Front toe actual: .11 Right front toe actual: .07

(Its 3/10') off so its not that bad and its the easiest part and the last to adjust)

Camber spec: -0.5 to 0.0' ( Ideally I prefer to have about -1.2 to -1.5' to help on hard corners)

Left Camber: -1.4' Right camber: .1'

(Positive camber=bad!)

Front Caster spec: 3.5 to 4.0'

Left Caster: 1.1 Right Caster: 6.0'!!!!!!

( This has to be what pulls my car to the side, a difference of 4.9' side to side is really off)

So besides replacing all of my control arms, what are my options? fully adjustable tubular arms?

Reply With Quote

Reply With Quote